Overview

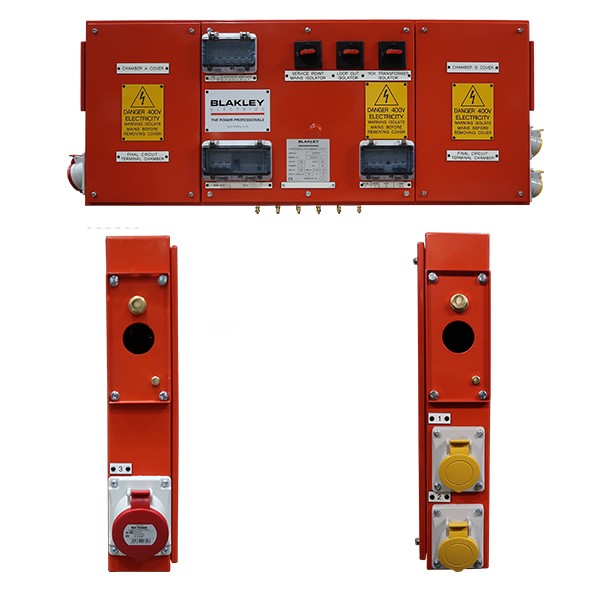

A lot of factors can drive the design of equipment to be installed in tunnels: the available space is often a key consideration, particularly for items to be installed into existing tunnels. On a recent tunnel project, the design brief was for the enclosure to be a maximum of 100mm in depth with an additional 20mm allowed for covers and switch actuators. This was a particularly challenging requirement as a 110V 2kVA transformer had to be incorporated, which would usually dictate an enclosure depth of over 200mm (plus fitments). In the end, an overall depth of 116mm was achieved.

The key to achieving such a reduction in depth was the incorporation of a toroidal transformer, in preference to a conventional shell type transformer. The specially designed core had a depth of only 90mm, which made all the difference. Toroidally wound transformers can still be double wound and provide a 110V Reduced Low Voltage (RLV) supply in accordance with BS7671, the IET wiring regulations. A toroidally wound transformer also has lower losses than an equivalent shell type transformer core, which reduces the amount of heat to be dissipated within the compact, stainless steel, non-vented enclosure.

Due to the presence of acid water in the tunnels, the enclosures were made from stainless steel with a high quality polyester powder coat finish, to ensure a long working life in a harsh environment (over 20 years). The enclosure also incorporated incoming and outgoing termination chambers (at opposite ends), enabling a 4 core, SWA cable with a cross section of up to 95mm2 to supply multiple Power Clusters on a single circuit.

On the distribution side, the Power Cluster incorporated a 32A, 3P+N+E, 400V socket to BS EN 60309-2 with TP MCB and 4P 30mA sensitivity RCD protection. A single-pole type D MCB fed the 2kVA, 230:110V RLV transformer, which in turn fed 2 no. 16A, 2P+E, 110V sockets to BS EN 60309-2, protected by a 16A, DP MCB. The Power Cluster also incorporated SP MCBs and contactors to feed the permanent tunnel lighting, which was automatically controlled by movement detectors.

If you would like to discuss a special Power Cluster, please contact the Blakley Projects Team.

Project No:

SP074

Industry

Industrial Building Services, Rail

Category

Permanent Distribution

Year

2020

Download PDF